Discover the game-changer in compressor technology: Venti compressors with Variable Speed Drive (VSD). With inverter-driven motors that adjust speed based on demand, these compressors deliver consistent performance while saving energy.

Energy efficiency: VSD vs fixed speed compressors

A VSD compressor adjusts its motor speed through an inverter to match real-time air demand, minimizing energy waste. The controller monitors airflow and pressure to maintain target values and can activate standby mode when speed reaches its minimum threshold.

Flexible solutions

Our Venti VSD range offers a variety of configurations from tank-mounted, base-mounted, or full-featured, to suit any industry or application.

Advantages of a Variable Speed Compressor

- Reduced energy consumption (in the proper application)

- Quieter than a fixed speed when running at a lower RPM

- Consistent plant pressure – increased component lifetime

- Less maintenance cost and ease of maintenance

- Low inrush current during motor starts

- Compact total solutions available

Comparing fixed and variable speed compressor costs

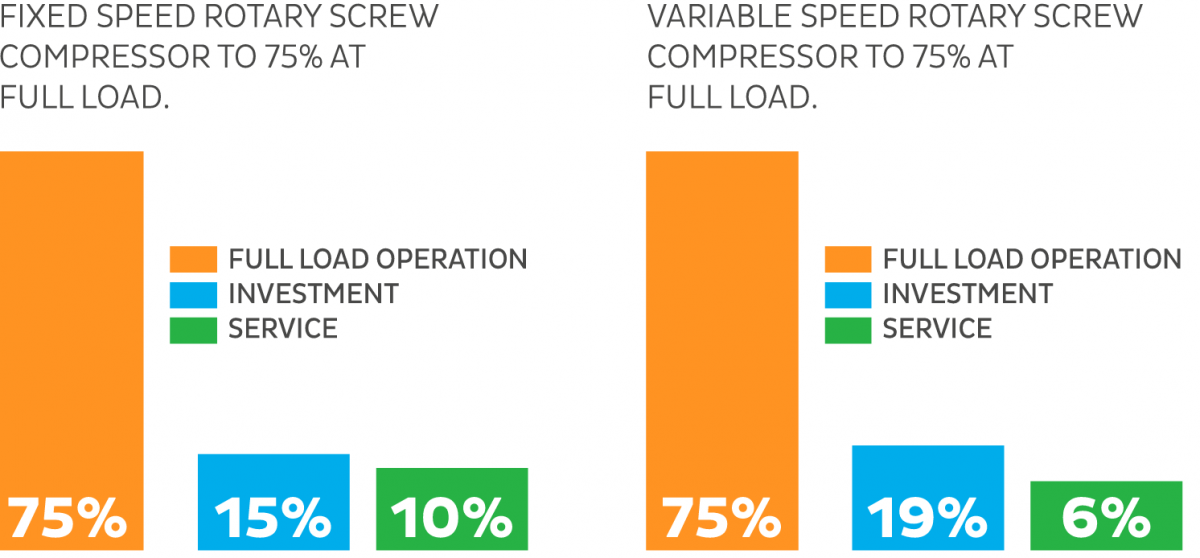

The graph compares the cost breakdown between a fixed-speed rotary screw compressor and a variable speed drive rotary screw compressor, both operating at 75% full load.

While both systems spend around 75% of total costs on full-load operation, the VSD compressor demonstrates clear savings over time.

Although the initial investment in a VSD compressor is slightly higher (19% vs 15%), this is offset by significantly lower service costs over the life of the compressor (6% vs. 10%) The VSD compressor’s ability to adjust speed to match air demand reduces wear and energy use, leading to lower maintenance requirements.

This is on top of the considerable ongoing energy savings to be made with a VSD compressor when installed in the correct application.