Compressed air powers countless industries across Western Australia – from mining to manufacturing, transport to food processing. But like any industrial process, compressed air isn’t immune to contaminants.

Every compressor produces moisture and oil vapour as a natural by-product. If left unmanaged, these contaminants can:

- Compromise efficiency

- Damage equipment

- Increase operating costs

- Put your business at risk of breaching environmental compliance.

This is where an oil-water separator becomes essential.

Compliance, protection, and peace of mind with an oil-water separator

Environmental regulations are tightening worldwide, and Western Australia is no exception.

An oil-water separator isn’t just a “nice to have”; in most compressed air applications, it’s essential.

By installing an oil-water separator, you’re not only protecting your compressed air system and avoiding unexpected downtime, you’re also:

- Reducing your environmental footprint

- Protecting your reputation

- Safeguarding your bottom line from fines or costly system failures.

Simply put: oil-water separators are a reliable, cost-effective, and practical solution for protecting both your business and the environment.

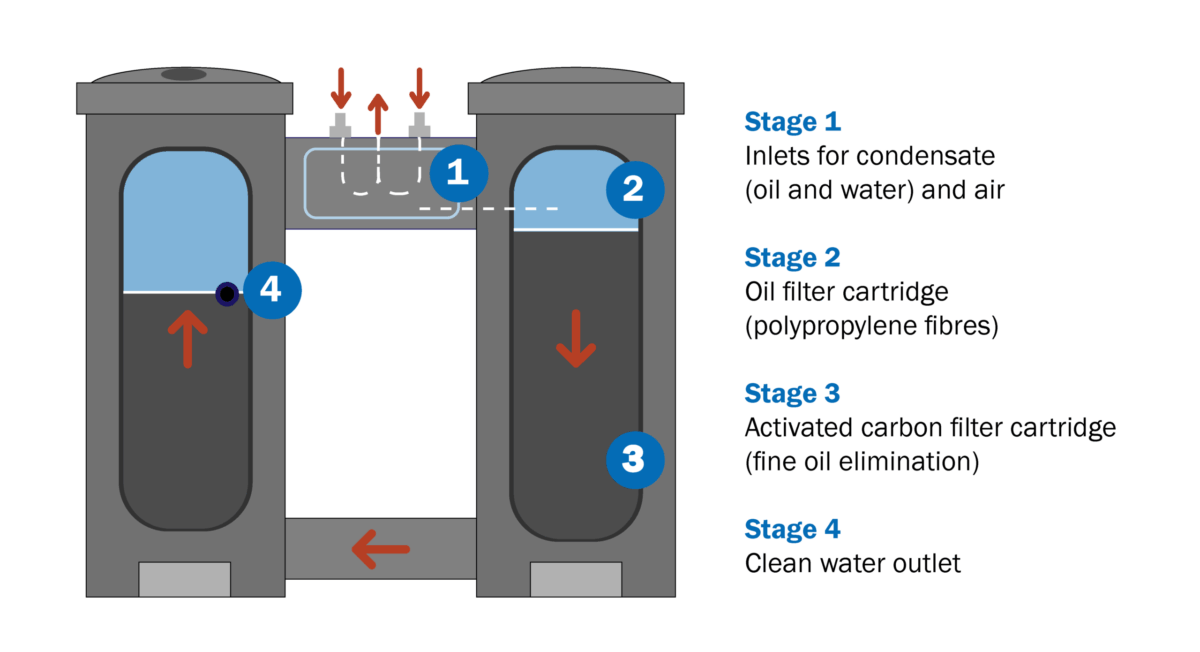

How do oil-water separators work?

Oil–water separators remove oil from compressor condensate using multi-stage filtration. First, oil is captured by specialised fibres that attract and hold it, while water passes through. The condensate then passes through additional filters to remove even the tiniest oil particles, leaving clean water that can be safely discharged to an approved sewer drain or catchment waste area.

Key features of your oil-water separator

- Visual element life indicator

- Overflow indicator to prevent spills

- No need for a settling tank

- Brass valves at each tower for easy servicing

- Fully compatible with most drain systems

An oil-water solution for every application

No two compressed air systems are the same, and neither are the demands placed on them.

The oil-water separators supplied and installed by Nessco Pressure Systems can tackle a wide range of compressed air applications:

- Small systems with a low condensate flow (up to 70 CFM)

- Large industrial systems with flows of up to 2500 CFM

With advanced filtration elements – such as treated polypropylene and a carbon polisher – our oil-water separators deliver consistent separation performance, no matter the lubricant or drain system in use.

For larger installations, maintenance is straightforward. With brass connections, easy-access servicing, and compatibility with virtually all drain systems, downtime is minimised and reliability is maximised.

Arrange installation of an oil-water separator today

An oil-water separator isn’t just an accessory – it’s a smart investment in performance, compliance, and sustainability. By taking a proactive approach, you’ll keep your compressed air system running smoothly while staying ahead of maintenance and environmental requirements.

To find out which oil-water separator is right for your system, contact our compressed air specialists on 1300 290 638 or email info@nesscopressure.com.au.