Every air compressor depends on a stable, well-balanced electrical supply.

When voltage, current or resistance fall outside their normal range, your compressor can lose efficiency, struggle to start, or shut down unexpectedly.

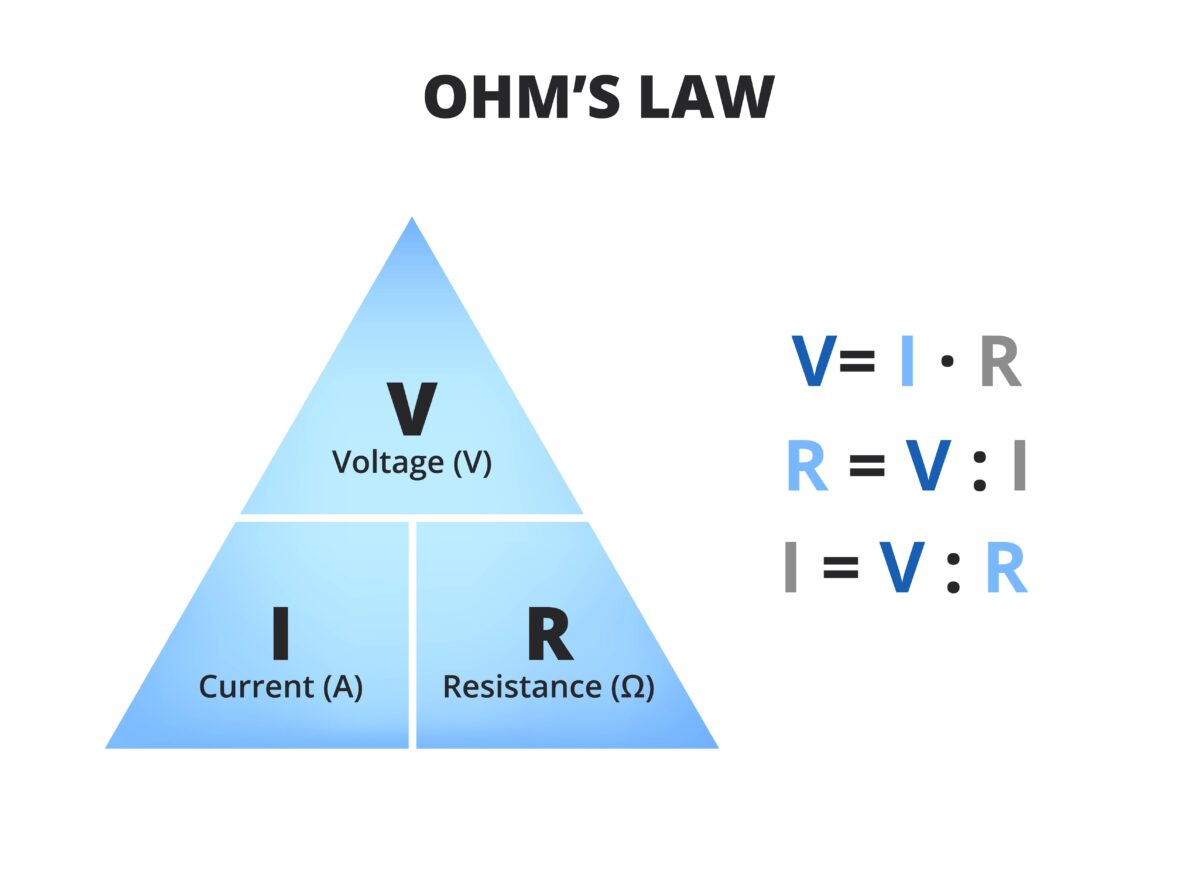

A simple electrical principle, Ohm’s Law helps explain why this happens and what it means for the long-term reliability of your compressed air system.

This blog breaks down Ohm’s Law in practical terms and highlights how it applies specifically to the air compressors you have at your workshop, production facility or worksite.

Practical uses of Ohm’s law during compressor maintenance

When servicing or troubleshooting compressors, the principles behind Ohm’s Law guide several of the tests our service technicians and electrical contractors use to find the problem:

Measuring motor winding resistance

This helps confirm whether the compressor’s motor is electrically balanced and operating safely.

Identifying cable or connection faults

Abnormally low or inconsistent resistance can reveal damaged wiring or poor connections.

Investigating start/stop faults

Current measurements can reveal if the motor is under mechanical load or if there’s an electrical imbalance.

Verifying system efficiency

Correct voltage and current levels ensure the compressor runs smoothly, reducing wear and saving energy.

Safety tips when working around electrical components

Of course, anyone inspecting the electrical side of a compressor should be qualified to do so, and follow the basic safety steps:

- Always isolate the power supply before opening panels

- Use test instruments correctly and cautiously

- Keep moisture and debris away from electrical enclosures

- Leave in-depth diagnosis to trained, licensed professionals

Electrical issues can escalate quickly — don’t risk investigating performance issues yourself. Safety should always come first.

How Nessco Pressure Systems keeps your compressor running at its best

Our service technicians are trained to identify electrical issues early through detailed inspections and testing. Nessco Pressure Systems offers:

- Electrical assessments of compressor systems

- Voltage, current and load testing

- Identification of voltage drop and wiring problems

- Motor repairs, rewinds, and replacements

- Preventive maintenance tailored to your equipment

We aim to keep your compressed air system running efficiently, safely and with minimal downtime.

Better electrical understanding equals better compressor performance and service

Understanding how voltage, current and resistance work together helps explain many of the performance issues that compressors experience.

By applying the principles behind Ohm’s Law, it becomes easier for our service technicians to identify electrical problems early and keep your system running reliably.

Book your compressor service today

Whether you need regular compressor servicing, or you’d like a compressed air specialist to assess your compressor’s performance, including its electrical condition, our service team can help.

Contact us using our dedicated contact form or call 1300 290 638.