Correct compressor location: maximising performance and reducing operating costs

Just like in the real estate game, when it comes to installing your compressor, location is important.

In fact, installing your compressor in the correct location can save your business time and money, so it’s a decision you want to get right.

You’ll reduce servicing, repair and breakdown costs and extend the life of your compressed air system by installing your unit in an area that is well-ventilated, clean, dry, dust-free, and easily accessible for servicing and maintenance.

Factors to consider when choosing a compressor location

When choosing a location for your compressor, consider these seven key factors.

Ventilation

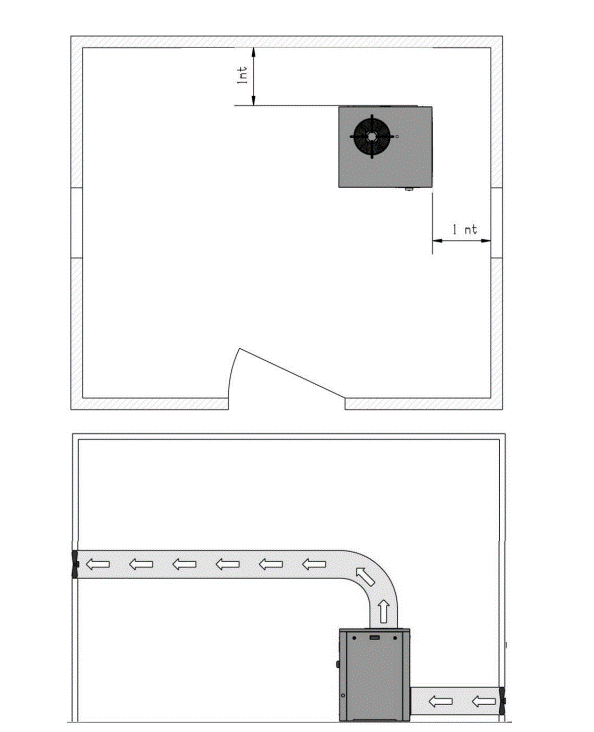

Cool air needs to be able to flow around your compressor, so the area you choose must have either natural ventilation or alternate ventilation, such as exhaust fans or ducts.

If your compressed air equipment is too close to other heat-generating machinery, hot air from one piece of equipment could be drawn into another, meaning your compressor has to work harder. Similarly, positioning your compressor too close to the roof, walls, or other solid objects can limit proper ventilation.

If your compressed air system has a dryer, never block the ventilation grid, even partially.

The diagrams below show the recommended one metre distance from all walls around the compressor (top diagram) and appropriate ventilation, both above and below the compressor in the form of exhaust fans or ducts (bottom diagram).

Protection

Ensure your compressor is protected from natural elements including rain, sunlight and recirculated hot air. Your compressed air systems should also be protected from other elements such as toxic or flammable materials and corrosive element like ammonia, chlorine, salt spray, and other chemicals which can cause erosion, contaminate the oil and damage the filters.

Moisture

Your compressor must be installed in a dry environment. Water and excess moisture can cause your compressor to overheat, lead to corrosion or contamination, damage your filters, wash away lubricants and oils inside your compressor and lead to receiver/tank and valve damage.

Dust, overspray or blasting sand

Select a clean, dry area when installing your compressor. Do not install your machine too close to other equipment or areas which generate or produce dust, overspray, blasting sand or similar particles.

Dust will cause wear to the compressor element, valves, filters, compressor oil and any moving parts.

This can increase the risk of breakages and expensive repairs to your system (and the equipment using compressed air such as drills, wrenches, and spray guns).

Temperature

Your compressor (and dryer) must be installed in a cool, well-ventilated area. Air compressors generate heat, and an area that’s too hot will make your compressor work harder and require more maintenance.

Accessibility

Depending on your compressor, your service technician may need a certain level of clearance to access the machine for maintenance or repairs. Allow an approximately one metre radius around your compressor so that any doors or panels can be opened or accessed during servicing.

Cleanliness

Maintain a clean area around your compressor, free from boxes, parts, rubbish, or other materials.

It’s also important to consider the compressor’s proximity to employees for noise and vibrations. If your compressor is installed too close to offices or employees not wearing PPE as part of their role, the noise and vibrations generated by the system could present a health and safety issue.

Expert advice and installation with Nessco Pressure Systems

Our technicians will inspect the area before installing new compressors and work with you to ensure correct positioning of your new compressed air system.

If you’re concerned about the location or performance of your compressed air system, get in touch with our compressed air experts by calling 1300 290 638 or emailing info@nesscopressure.com.au.

We’ll provide solutions to make sure your machine is in the best location to help maximise the life of your compressor and minimise your ongoing service and repair costs.