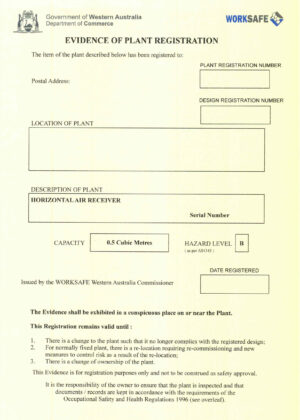

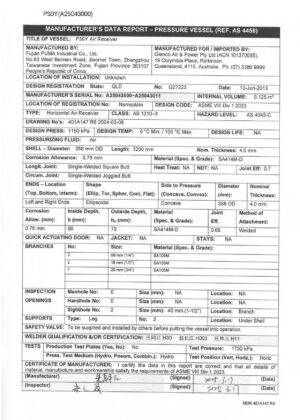

AS 3788:2024 – Pressure Equipment: In-Service Inspection

This standard outlines the minimum requirements for inspecting pressure equipment in service and ensuring it remains fit for use. It covers repairs, modifications, alterations and re-rating of both new and used pressure equipment. The requirements apply throughout the entire life of the equipment, from commissioning to final disposal.