A Compressed Air Dryer is used for removing water vapour from compressed air.

Humidity is a component of atmospheric air, which can be found in the form of condensate and/or vapour in compressed air distribution systems and the machines that use the compressed air.

If the condensate can be easily separated and discharged, humidity, in the form of vapour, will follow the compressed air flow all the way to the final product. When it then cools, a part of this humidity present in the compressed air condenses and over time causes serious damage to the distribution network, the machines using the compressed air and the final product.

How Air Dryers Work

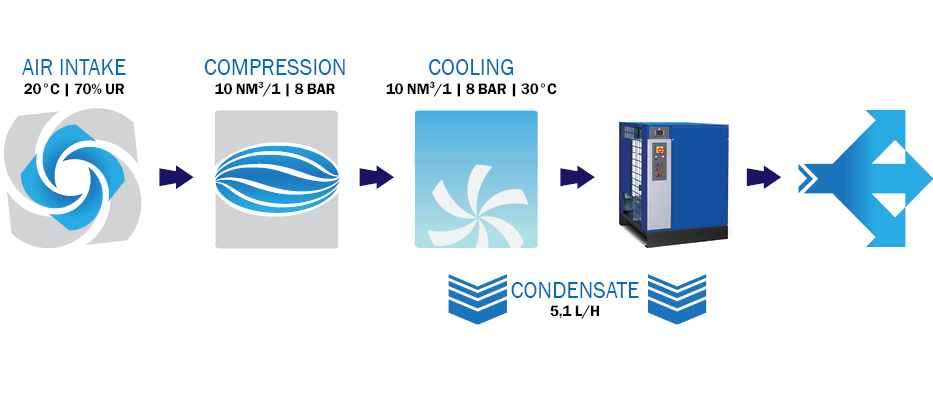

For example, 5.1 l/h of condensate is separated from a compressor with an output capacity of 10 Nm3/min and an ambient intake air temperature of 20°C and 70% relative humidity, whilst operating at a delivery pressure of 8 bar (g) and cooling the air to 30°C.

If the compressed air is then dried even more to a dewpoint of +3°C, a further 1.7 l/h of condensate can be separated.

If you require a new Dryer please contact our NPS Compressed Air Equipment Specialists on 1300 290 638.